Frequently Used Materials

Not only can we mold elastomers into an endless possibility of shapes, we can also bond them to metals and other materials. We can customize the color, hardness, compression, elongation, chemical resistance, and other key physical properties to meet even the most demanding applications.

Butyl (IIR)

Chloroprene/Neoprene (CR)

Ethylene Propylene Diene Monomer (EPDM)

Natural Rubber (NR)

Nitrile - Carboxylated - Hydrogenated (NBR - XNBR - HNBR)

Polyisoprene (IR)

Silicone - Fluorosilicone (VMQ - FVMQ)

Styrene Butadiene (SBR)

Viton – Perfluoroelastomer (FKM - FFKM)

Other elastomers including custom in-house formulation

OUR PROCESSING CAPABILITIES

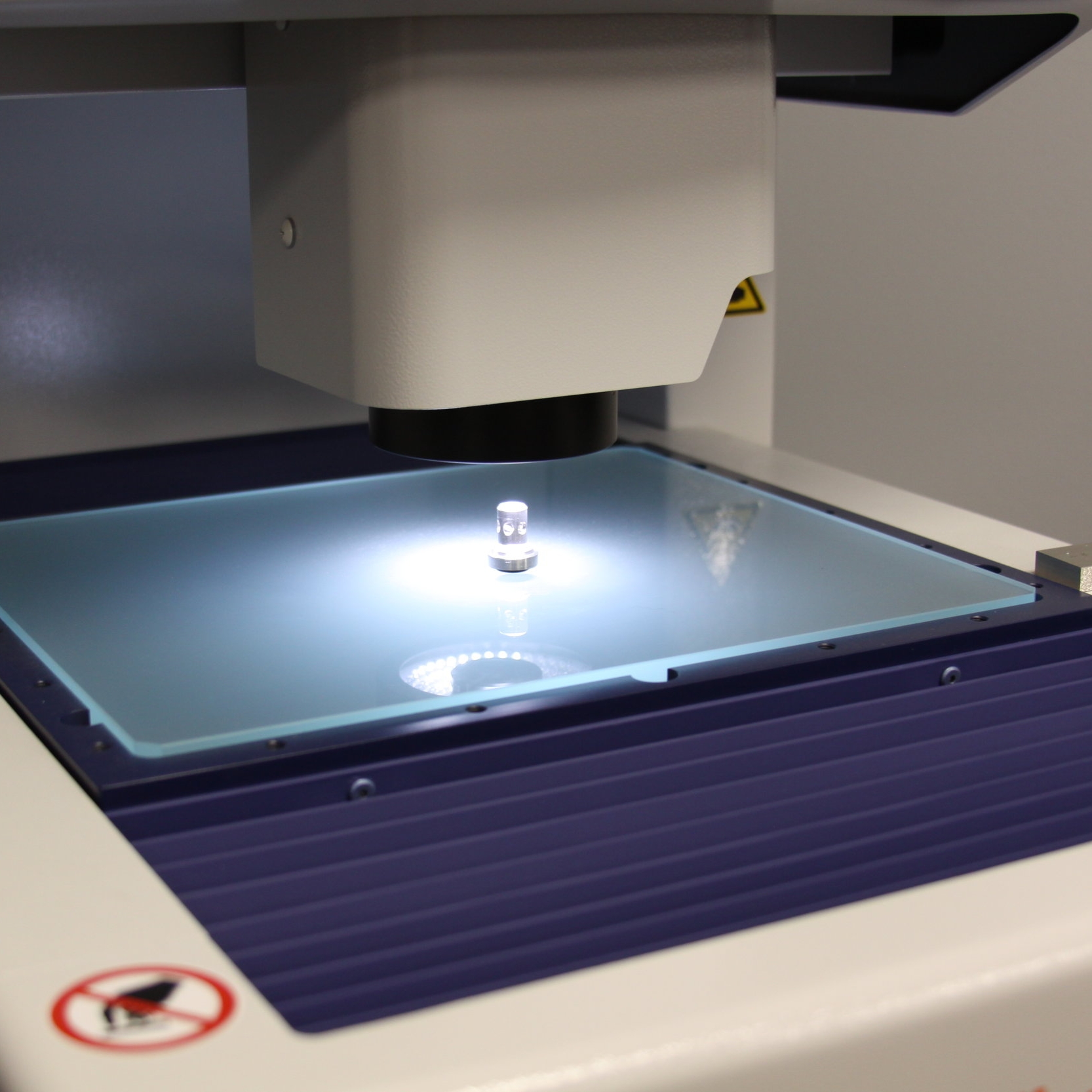

Jackson Flexible is equipped to provide compression, transfer, and injection molding of standard and custom compounds utilizing up to 450 ton presses and staffed by expert personnel in milling, molding, bonding and assembly. We have in-house tool and jig fabrication, extensive internal and external testing resources, and inspection protocols including laser dimension scanning.

Other value-add services include:

Design review/consult relative to molding feasibility and efficiency

Compound formulation review/consulting/spec requirements

Metal and other substrate preparation and adhesive application

Light assembly/special packaging

ENGINEERING- YOur PRODUCT DESIGN SUPPORT

Design assistance is offered to every client to optimize manufacturing processes. We produce prototypes with speed and accuracy and acceptable cost. Our In-house cavity/tool repair is available when needed and allows in-house preventative and/or emergency maintenance to insure timely delivery of in-spec products.

In-House Tooling: Your CAD, Our Machines